Designed with a hook or loop on each end, extension springs make it possible to connect many mechanisms across many industries. Like all springs, heavy duty extension springs store and absorb energy, however extreme stress will limit their performance. To get the most out of your extension springs, let Mid-West Spring and Stamping assist in the design and production.

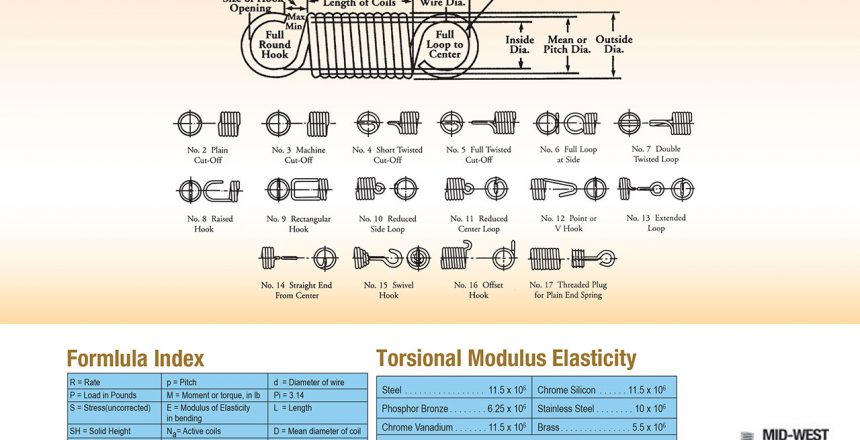

Extension springs typically have the same function, but can be designed in slightly different ways to help fit their needs best. Spring ends include threaded inserts, extended twist loops, crossover central loops, hooks, expanded eyes, reduced eyes, rectangular ends, or teardrop-shaped ends. Modifying the extension spring, either in its end or length of coil, allows them to fit many functions.

You are likely to come across an extension spring somewhere in your everyday routine. For instance, garage doors need extension springs to open and close, and your car requires extension springs in both its interior and exterior applications. Children need extension springs in some of their toys or to enjoy the bounce of a trampoline.

Small extension springs are used in tools like pliers, or in essential medical devices. Larger machinery requires larger extension springs, such as large brake springs for off-road vehicles or farm machinery.

When extension springs are used in collaboration with each other, they share the load when it comes to being stressed. If there is damage to one spring, then all other springs must work harder to make up for the one’s absence. Those scenarios mean that each spring is now more likely to become damaged as well, shortening the lifespan of the extension springs.

Mid-West chooses from a variety of materials, types, and shapes to craft extension springs to meet your application’s needs. Join the multitudes of customers that rely on us to optimize the fit, form, and function for their desired outcomes at a competitive cost. Request a quote today, or call us at 800-424-0244.