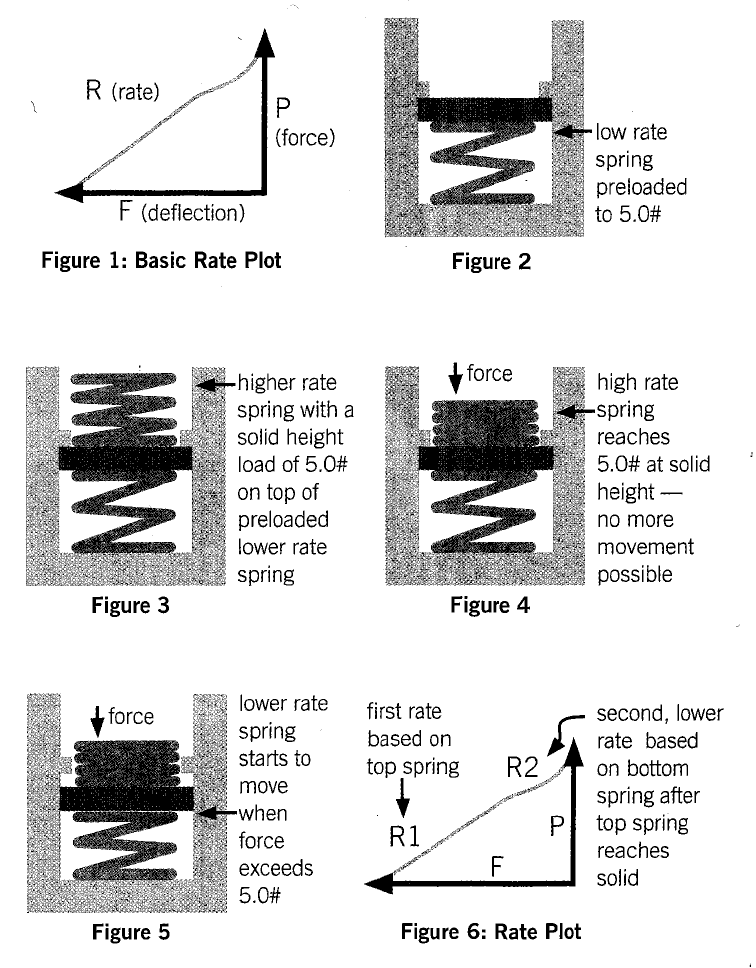

As shown in the previous article, a rate graph is made from the two components of force and deflection. When a spring moves, the force applied creates a deflection — the spring moves and pushes back with the same force that is applied. As it travels, the rate of the spring will stay consistent until there is substantial coil loss. This basic rate graph is shown in Figure 1.

But, what if the spring rate needs to decrease? How can this be accomplished?

To have a decreasing rate, two springs will be needed. The first spring is preloaded to a given load and captured in that preloaded state.

For example, a spring with a rate of 10 #/inch is captured with a .500” deflection. This produces approximately 5.0# of force. This means a force of greater than 5.0# will be needed to make the spring move. Figure 2 shows the first spring in position.

The next step is to set a second higher rate spring on top of the preloaded spring. Let’s assume the top spring has a spring rate of 20.0 #/inch. It will require a movement of .250” to create 5.0# of force. The final set-up looks like Figure 3.

As force is applied, the top spring starts to move. The pitch is set so the top spring reaches solid height after a .250” deflection. The top spring is now completely closed and can no longer move (see Figure 4).

As force continues to be applied, the bottom spring will now move because the force has exceeded 5.0# (see Figure 5).

Since the bottom spring is a lower rate spring, the combination of the two springs now produces only the rate of the bottom spring. This will generate a rate plot as shown in Figure 6.

The key to the success of this system is to be sure the top, higher rate spring’s solid height load matches the preload of the bottom, lower rate spring.

When the top spring has reached the end of its deflection capability, the bottom spring kicks in and begins the lower rate scheme.

This system makes it possible to deliver any rate change needed by cleverly matching one spring’s closing force to the other spring’s preload force. Simple, but very effective for the right application.

By: Randy DeFord, Engineering Manager Mid-West Spring & Stamping