Advantages

Disadvantages

When a compression or extension spring moves the material is in a state of torsion. This means the wire is actually twisting as it moves, not bending. This twisting causes the wire to be under stress as it moves, ever increasing as the spring gets closer and closer to solid height. If the pitch of the spring is too high, the spring could reach a point where the stress is beyond what the material can withstand and it will yield to the force, taking a permanent set.

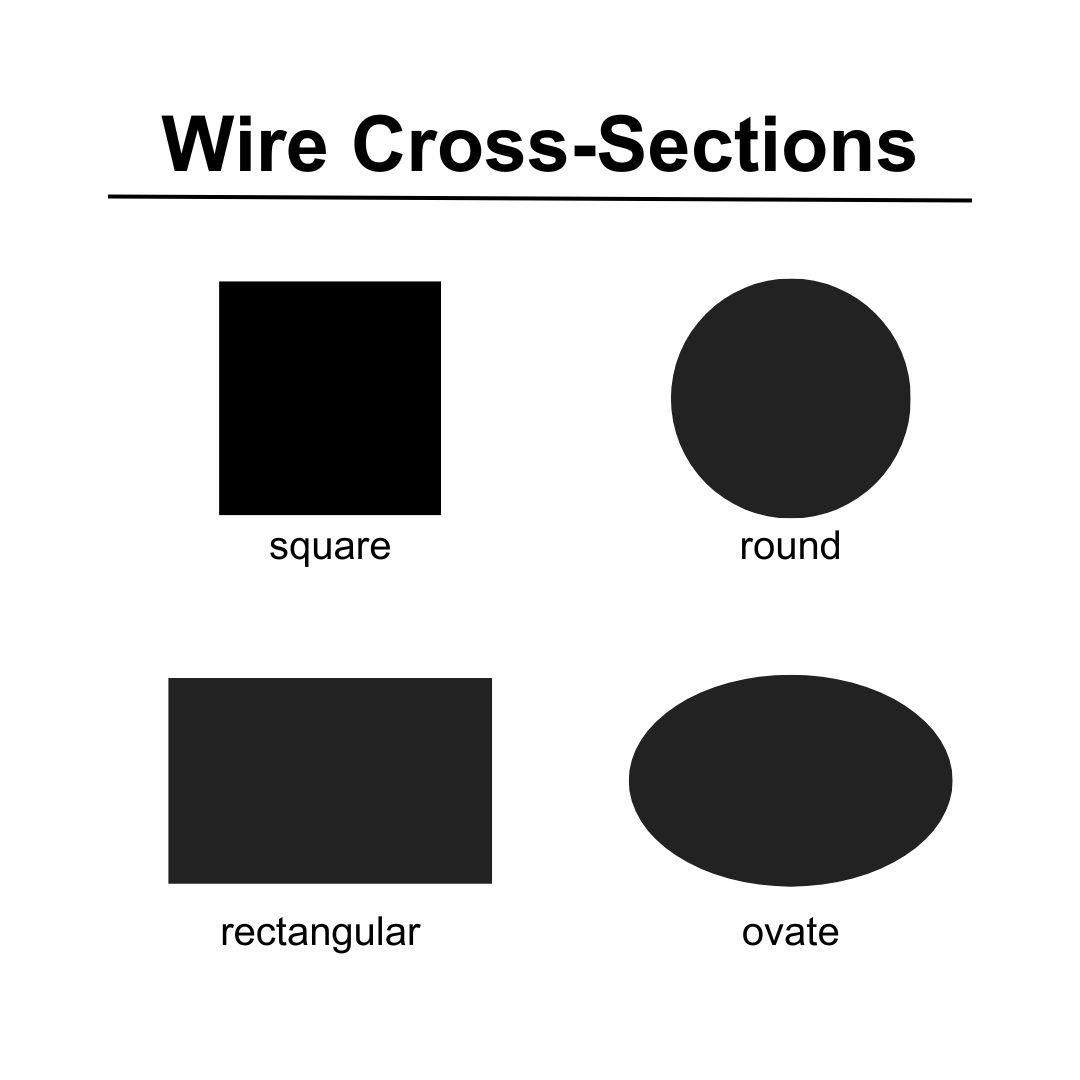

Square or rectangular wire reacts to the same stress, but the distribution of that stress is not as uniform and predictable as round wire. Since excessive stress can translate directly to breakage, a non-round cross-section will break earlier in its life than a comparable round shape.

In summary, round wire will go farther with less stress and set, but will not produce the same rate/ force in the same travel. As with most things in the mechanical world, when you gain one attribute, you lose another.

Corner Shape

Another disadvantage to using square or rectangular wire is the corner shape. There are three basic corner conditions: square corners, round corners and round edge. Square edge is the worst for stresses, but produces the highest rate. Round corners are better for stresses, but lose some rate potential because some wire is, literally, missing in action. A rolled round edge will have the least rate potential, sometimes as much as 10 to 15 percent less, but may have higher life due to its partial round geometry.

Without doubt, the most negative factor of non-round wires is their availability. Round wire is available in many stock sizes that can be ordered and arrive the next day. In square and rectangular sizes, material may need to be custom shaped, which increases the delivery time to the customer. Also, a minimum amount of material may be required, perhaps 20,000# to justify the cost of tooling and set-up charges for a special size.

Surface Condition

Another factor that is often not considered is surface condition. Any type of spring design lives or dies due to its surface condition. Any and all imperfections in the material surface can promote early failure. A design that is calculated to have a high life cycle will break early if there are any appreciable surface scratches, nicks or tool marks.

Rolled Wire Corner

Also, rolled wire corner can have its issues. It is common to take either a square wire or round wire and roll them in a wire rolling machine, through sheer force, into a given rectangular shape. The pressure exerted against the side during the “squeezing” can increase the wire hardness. That may seem like a nice asset to obtain a harder material, but it depends on how hard the resulting wire becomes. Many times, to achieve a needed cross section, let’s say .125” x .375”, the starting material will need to be rolled/squeezed more than once. Each pass will increase the hardness. Finally, when the finished product reaches the coiling machine, it will break into pieces as the coiling operator attempts to form it around an arbor. Wire that is too hard cannot be formed and is unusable for producing formed helical springs.

For some applications where the cold winding could produce cracking during forming, square/ rectangular wire springs are formed in the annealed condition and then heat treated.

So, non-round wire shapes will give you more bang for your buck, but the trade-off is usually in spring life. As with all things mechanical, there is always a limit and the shape of the wire has a lot to do with that potential.

Round wire will go farther with less stress and set, but will not produce the same rate/force in the same travel. As with most things in the mechanical world, when you gain one attribute, you lose another.

By: Randy DeFord, Engineering Manager Mid-West Spring & Stamping